Production

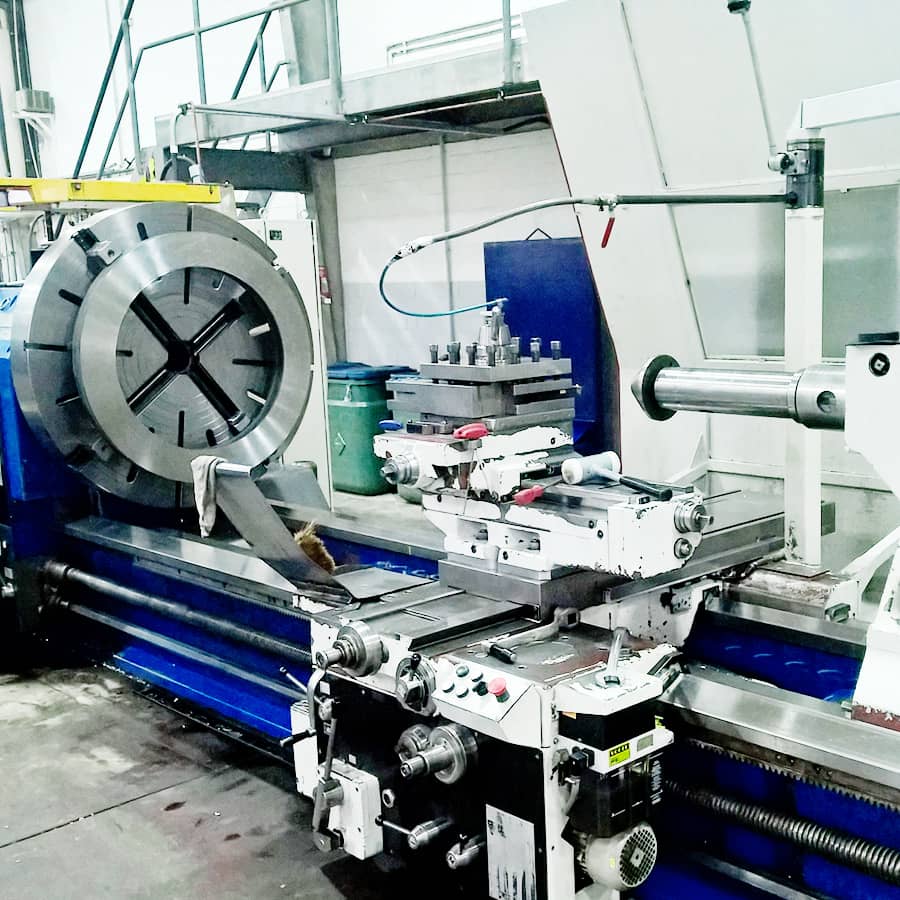

CNC machining center: precision manufacturing at the highest level in Sachsenheim.

Discover the flexibility and individuality of our in-house manufacturing – Your partner for custom centrifuges and spare parts. We are proud to offer a manufacturing solution perfectly tailored to your specific needs. Whether it concerns building custom-designed centrifuges or producing custom-made spare parts, we have the expertise and technological equipment to ensure the highest precision and quality. We also provide precise replacement parts for older machine models to ensure a long service life and optimal functionality of your equipment.

Diverse manufacturing processes for customized solutions:

Milling

Precise and metal-cutting process for metalworking.

Drilling

Precise drilling with our drilling machines.

Turning

Shaping by rotary cutting of various materials.

Orbital welding

Joins materials by automatically rotating around the weld seam.

NC pipe bending

Tube forming through precise, NC-controlled bending into defined angles and shapes.

Sheet metal processing

Metal design by cutting, bending and shaping sheet metal.

Fast and uncomplicated: How to reach us:

Your direct line to us. We are available to answer all your questions about the centrifuge. Our 24/7 technical support hotline is available around the clock. If technical problems arise, our experts are ready to provide immediate assistance. Contact us now for assistance with your challenges.

Large component manufacturing: high-quality components from german suppliers.

In our large component manufacturing, we rely on high-quality components from selected German suppliers. This commitment to quality not only guarantees the durability and reliability of our products but also reflects our endeavor to meet the highest manufacturing standards.

Precision in Every Detail: Quality Assurance with State-of-the-Art Measuring Technology.

Our quality assurance stands out through the use of state-of-the-art measuring technology that ensures precision in every detail. This technology enables us to meet and exceed the highest quality standards in our manufacturing process.

Orbital and MAG welding: where technology and customer requirements merge.

We integrate orbital and MAG welding into our in-house manufacturing, thus providing a wide range of possibilities for individual customer requirements with utmost precision. Every welding process is precisely controlled. This allows us to achieve our high manufacturing standards and remain flexible in the production of individual parts.

Quality that impresses: NC tube bending meets the strictest standards.

With the advanced technique of NC-controlled tube bending, we achieve unparalleled flexibility in the manufacturing of systems. This method allows us to significantly accelerate the construction of our state-of-the-art centrifuges and plays a crucial role in retrofits and repair works. Thanks to the precise control over the bending process, we can ensure that each manufactured part exactly meets our strict quality requirements, distinguishing us as a leader in centrifuge technology.

High-quality enclosures & control cabinets: our quality promise.

Sheet metal processing is a part of our in-house manufacturing for centrifuge parts. We produce enclosures, control cabinets, and other specialized sheet metal parts, always aiming to adhere to the highest quality standards. Our flexibility allows us to respond to individual customer requests and provide customized solutions.

Fast and uncomplicated: How to reach us:

Your direct line to us. We are available to answer all your questions about the centrifuge. Our 24/7 technical support hotline is available around the clock. If technical problems arise, our experts are ready to provide immediate assistance. Contact us now for assistance with your challenges.