Contecma C. S. - Our expertise

Everything to do with centrifuges: We are your manufacturer-independent service provider!

Welcome to the world of centrifuge technology, where quality and versatility are the top priorities. As your manufacturer-independent partner, we bring a new dimension from mechanical engineering and centrifuge service to the right filter cloths and process optimization. Our team of experienced professionals uses proven methods to ensure the efficiency and longevity of your centrifuges.

More than just mechanical engineering: perfect service and maintenance for your centrifuge!

With us, service is not just a promise. Our service, process and project teams provide you with competent and personal support from the conception of new systems and process technology to the operation of your facilities.

Perfect filter cloths for the right application!

The filter cloth is one of the most important components in solid-liquid separation. The selection of a suitable filter medium, the fit of the cloth and the appropriate process parameters are key factors that determine the filtration and product quality as well as the cost-effectiveness of the entire filtration process.

Our process engineers will be happy to support you in optimizing your existing or new production.

By optimizing the selection of filter cloths and setting the process parameters, we are able to optimize the production of your product. This saves production costs and increases your production quality.

Fast and uncomplicated: How to reach us:

Your direct line to us. We are available to answer all your questions about the centrifuge. Our 24/7 technical support hotline is available around the clock. If technical problems arise, our experts are ready to provide immediate assistance. Contact us now for assistance with your challenges.

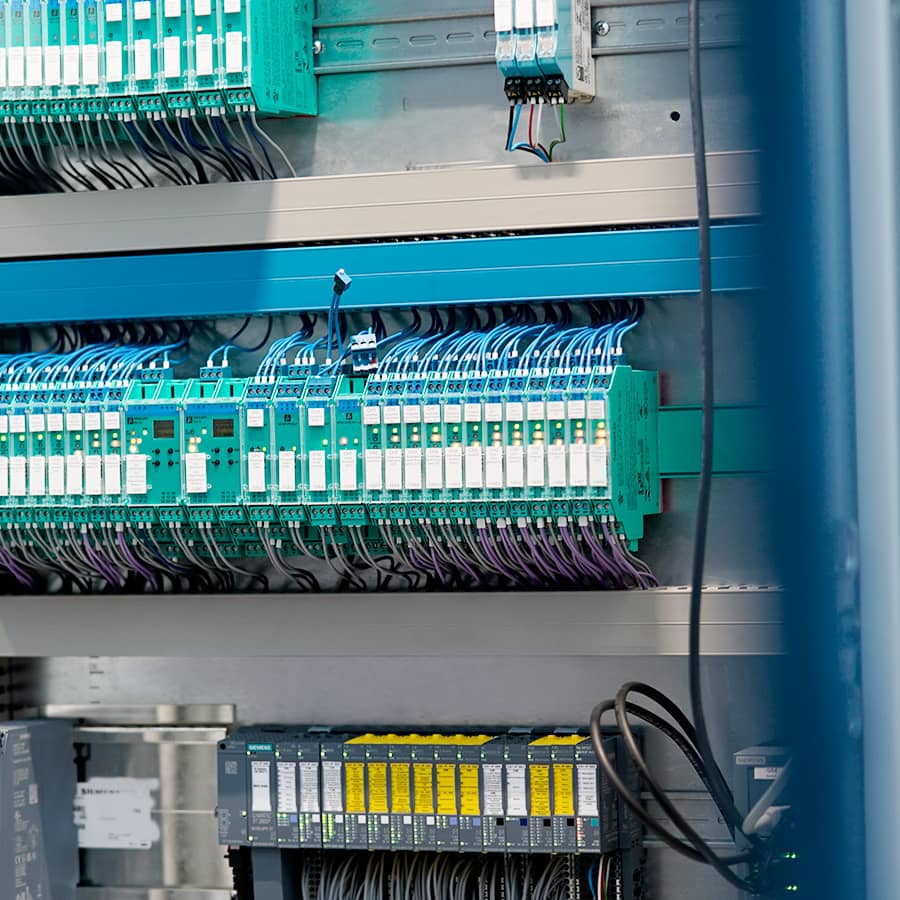

Professional system planning and control concepts: Your path to efficiency.

Our engineering team supports you in system planning and the implementation of control and visualization concepts. The CAD-supported 3D construction of mechanical components or the electrical design of control cabinets enables us to implement customer requirements quickly and cost-effectively. In-house switch cabinet construction and mechanical production round off this service.

Efficiency and performance: Our retrofitted centrifugals for your requirements.

By regularly purchasing used centrifuges, equipment and aggregates, which are overhauled in-house by our qualified personnel and brought up to the latest technical standard, we can react flexibly and quickly to customer requirements.

State-of-the-art, in-house production for milling, turning and drilling.

In order to meet all metalworking requirements, we rely on our modern CNC machining center in our production facility. This allows us to act flexibly and respond to special and individual customer requests. This ranges from rough machining to the smallest and finest detail work.