Filter cloths – filter materials

Quality and diversity: over 3000 filter cloth options for perfect filtration of your facility.

With over 3000 high-quality filter cloth qualities on the market, our expert is at your side to select the ideal filter fabric for your existing facility. Choosing the wrong filter material can lead to inefficient filtration – a risk we minimize with our wide range of options and expert knowledge. Our own filter cloth production facility allows us to respond promptly and flexibly to your individual requirements.

Partnership with fabric producers: quality that convinces.

Our close cooperation with leading fabric producers ensures that we always provide the best fabric for your applications in solid-liquid separation and dust removal, with a special focus on optimal filtration performance, durability, and cost-efficiency.

We are your reliable partner for customized filter solutions that are both high-quality and economical.

We standardly offer fabrics made of:

- Polypropylene (PP)

- Polyamide (PA)

- PEEK

- Polyester (PET)

- Fluoroplastics (ECTFE, ETFE, PTFE)

On request, we also supply cloths from other fabric materials.

Fast and uncomplicated: How to reach us:

Your direct line to us. We are available to answer all your questions about the centrifuge. Our 24/7 technical support hotline is available around the clock. If technical problems arise, our experts are ready to provide immediate assistance. Contact us now for assistance with your challenges.

Professional Yarn Combinations for Specific Filtration Tasks.

Our process technician selects the optimal yarn combination for each filtration task, focusing on the highest standards of purity and quality. This specialized selection guarantees that contamination of the filter cake by fabric fibers is effectively prevented, ensuring unparalleled filter performance.

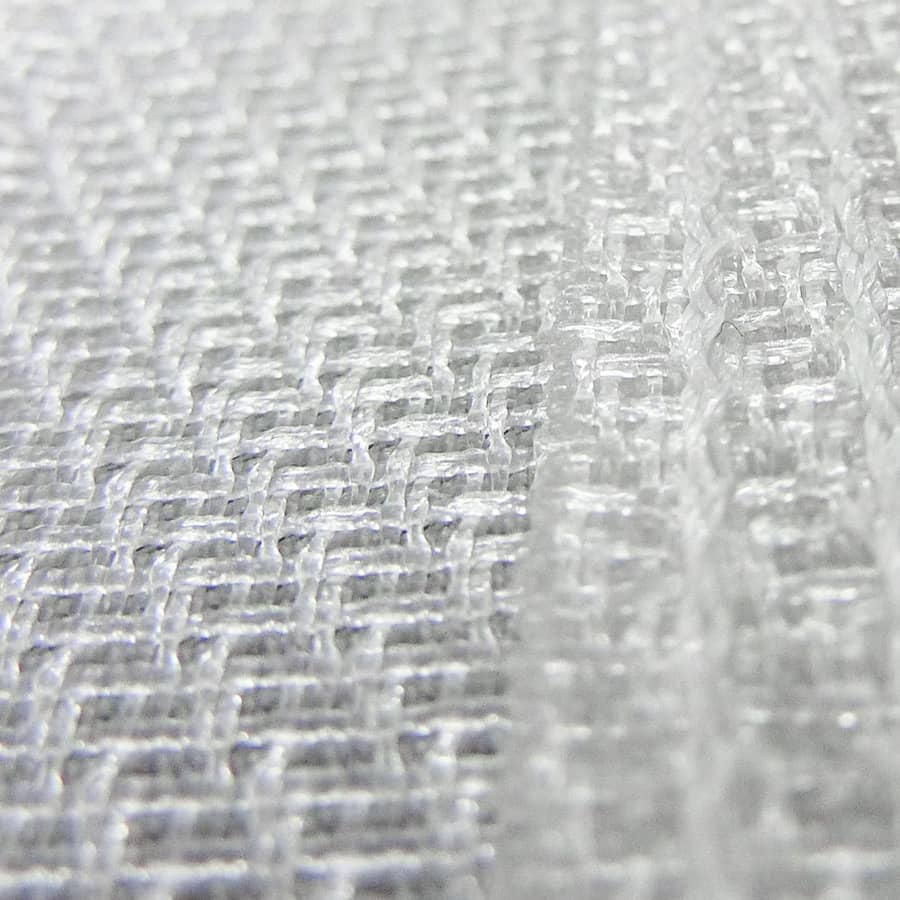

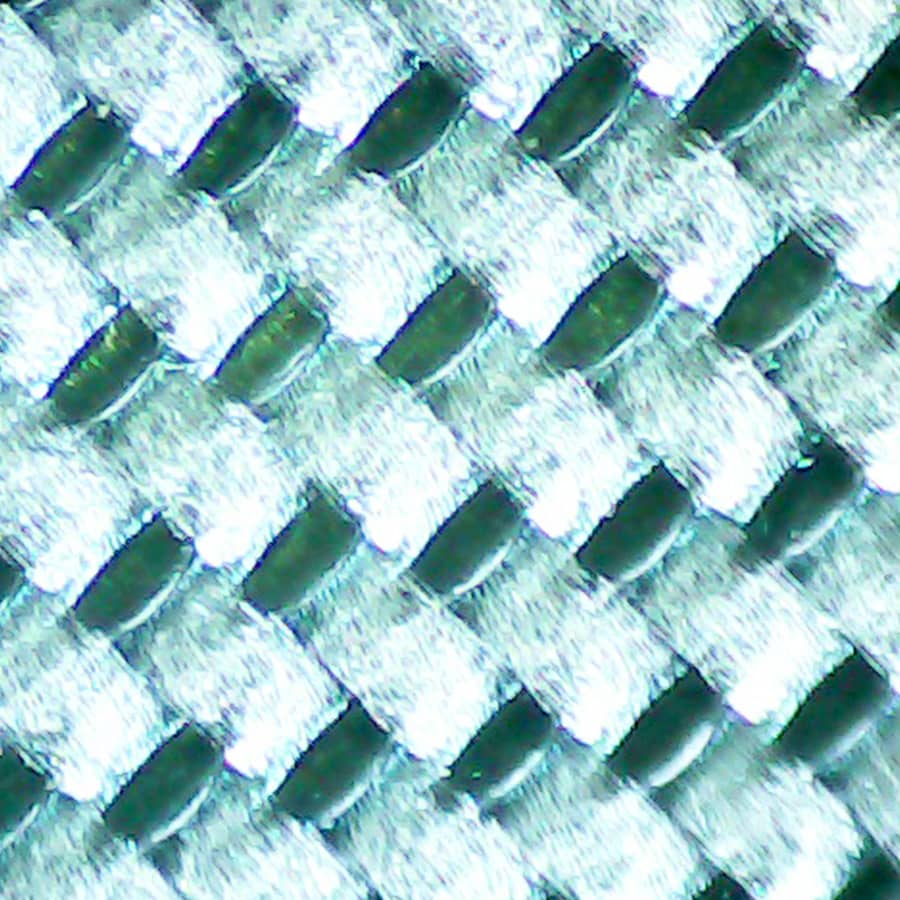

Overview: Manufacturing of Filter Fabrics on Modern Looms.

Our high-quality filter fabrics are produced on advanced looms, where we craft customized filter cloths through precise weaving of warp and weft threads. Depending on the specific requirements, we select from various thread types such as monofilament, multifilament, or staple fiber, to create versatile and effective filter fabrics. This selection allows us to offer a wide range of yarn combinations to meet the most diverse filtration needs.

Yarn combination - Multifil / Multifil

- Air permeability between 2-50 L/dm² min

- Universally applicable

- Medium filter resistance

- Conditional depth filtration

- Suitable for fine products up to 1 µm

- Good wear resistance

- Good abrasion resistance

- Shrinkage possible

- Clogging possible

Yarn combination - Monofil / Monofil

- Air permeability between 12-1200 L/dm² min

- Universally applicable

- No depth filtration

- Low filter resistance

- Suitable for fine products up to 2 µm

- Very good wear resistance

- Good abrasion resistance

- No shrinkage

- No clogging

- Thread breakage leads to cloth defect

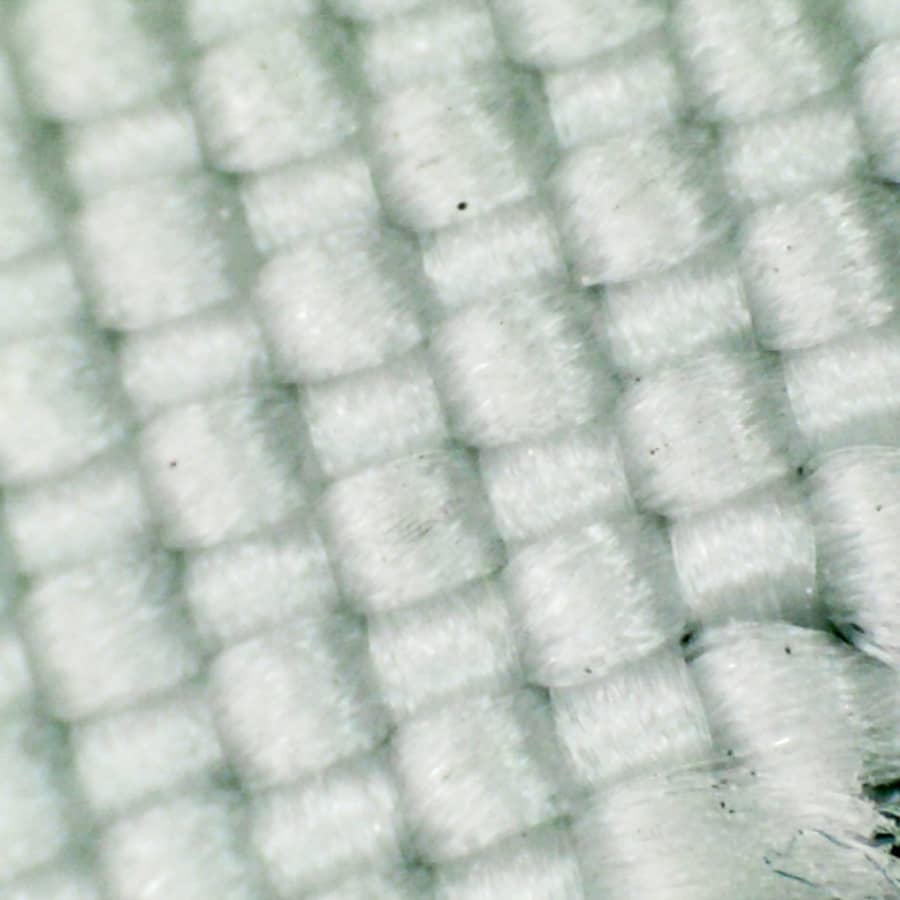

Yarn combination - Stapelfaser / Stapelfaser

- Air permeability between 2-120 L/dm² min

- Versatile use

- Pronounced depth filtration

- Suitable for fine products up to 0.5 µm

- Stable filter fabrics with good wear resistance

- Good abrasion resistance

- High filter resistance

- Shrinkage possible

- Prone to clogging

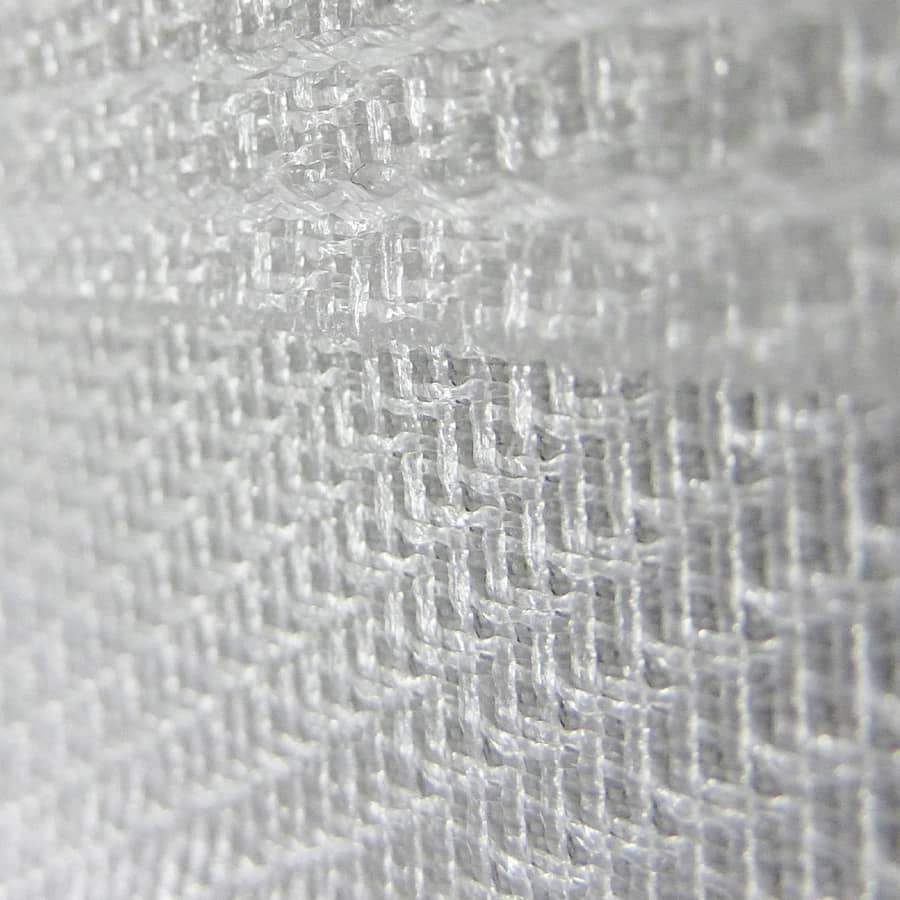

Yarn combination - Multifil / Monofil

The filter fabric with the yarn combination of multifilament / monofilament is the most commonly used combination. It combines the positive properties of pure, multifilament, and monofilament fabrics.

- Versatile use

- Low filter resistance

- Suitable for fine products up to 1 µm

- Very good wear resistance

- Good abrasion resistance

- Low shrinkage

- Low tendency to clog

Yarn combination - Multifil / Stapelfaser

Filter fabric with the yarn combination of multifilament / staple fiber merges the properties of both yarns. It is particularly well-suited for the filtration of small particles.

- Versatile use

- Pronounced depth filtration

- Improved filter resistance

- Suitable for fine products up to 1 µm

- Very good wear resistance

- Good abrasion resistance

- Low shrinkage

- Low tendency to clog

Fast and uncomplicated: How to reach us:

Your direct line to us. We are available to answer all your questions about the centrifuge. Our 24/7 technical support hotline is available around the clock. If technical problems arise, our experts are ready to provide immediate assistance. Contact us now for assistance with your challenges.